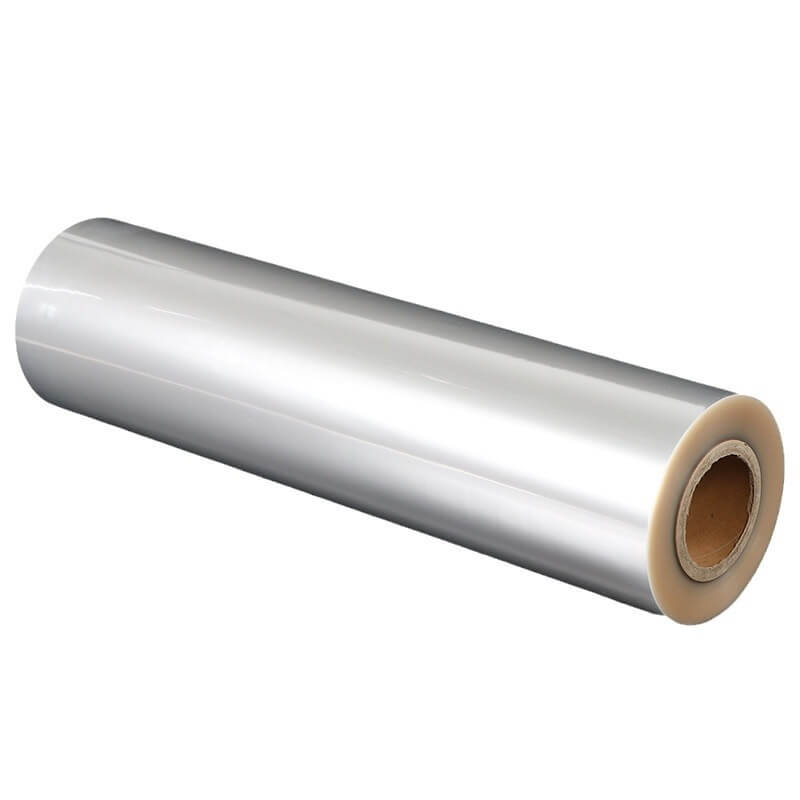

PE plastic film (Polyethylene Plastic Film) is a type of film made from polyethylene as the main raw material. It is known for its waterproof, flexible, and durable properties, making it widely used in packaging, agriculture, and clothing. In the context of raincoat production, PE film offers excellent waterproofing, lightweight, and soft characteristics, which makes it ideal for manufacturing disposable or lightweight raincoats.

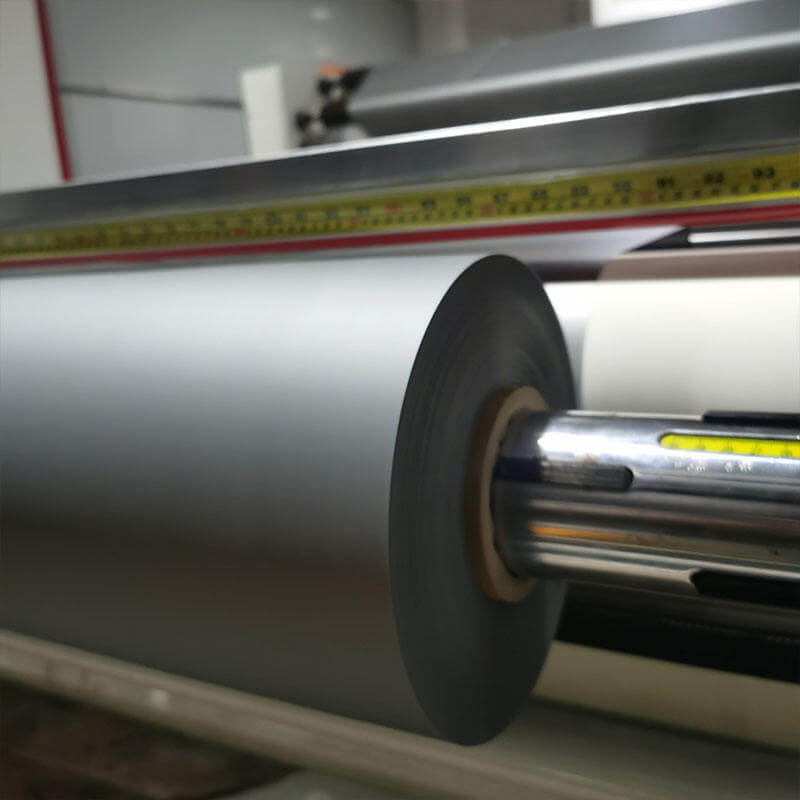

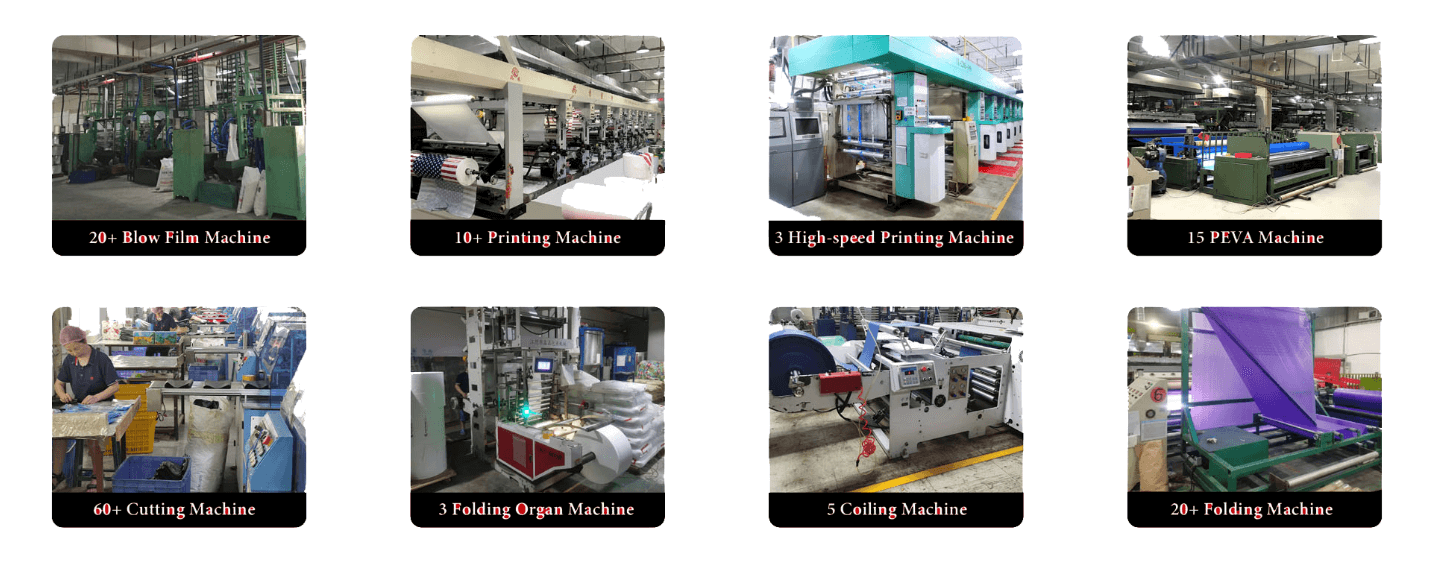

Printing Technology in Raincoat Production

To add personalized designs and aesthetic appeal to raincoats, printing patterns onto PE film is often required. However, the smooth surface and high chemical stability of PE material make it challenging for traditional printing methods to adhere the ink firmly. To overcome this, specialized printing techniques are used to ensure the ink bonds tightly with the surface of the PE film, thus enhancing the durability and waterproof qualities of the printed patterns.

How to Achieve Fade-Resistant Printed Patterns

The key lies in selecting the appropriate ink and printing process to ensure that the pigments in the ink securely attach to the PE film. After hundreds of experiments and tests, a specially formulated ink was developed that can bond well with the PE material. This ink allows for full-surface printing on the raincoat, ensuring vivid patterns that do not easily fade, even when exposed to rain.

This technology works by adjusting the ink formulation and printing temperature, promoting the chemical bonding between pigment molecules and the PE film’s surface. As a result, it allows for the mass production of fully printed raincoat materials, meeting the market demand for personalized designs and high-quality waterproof raincoats.