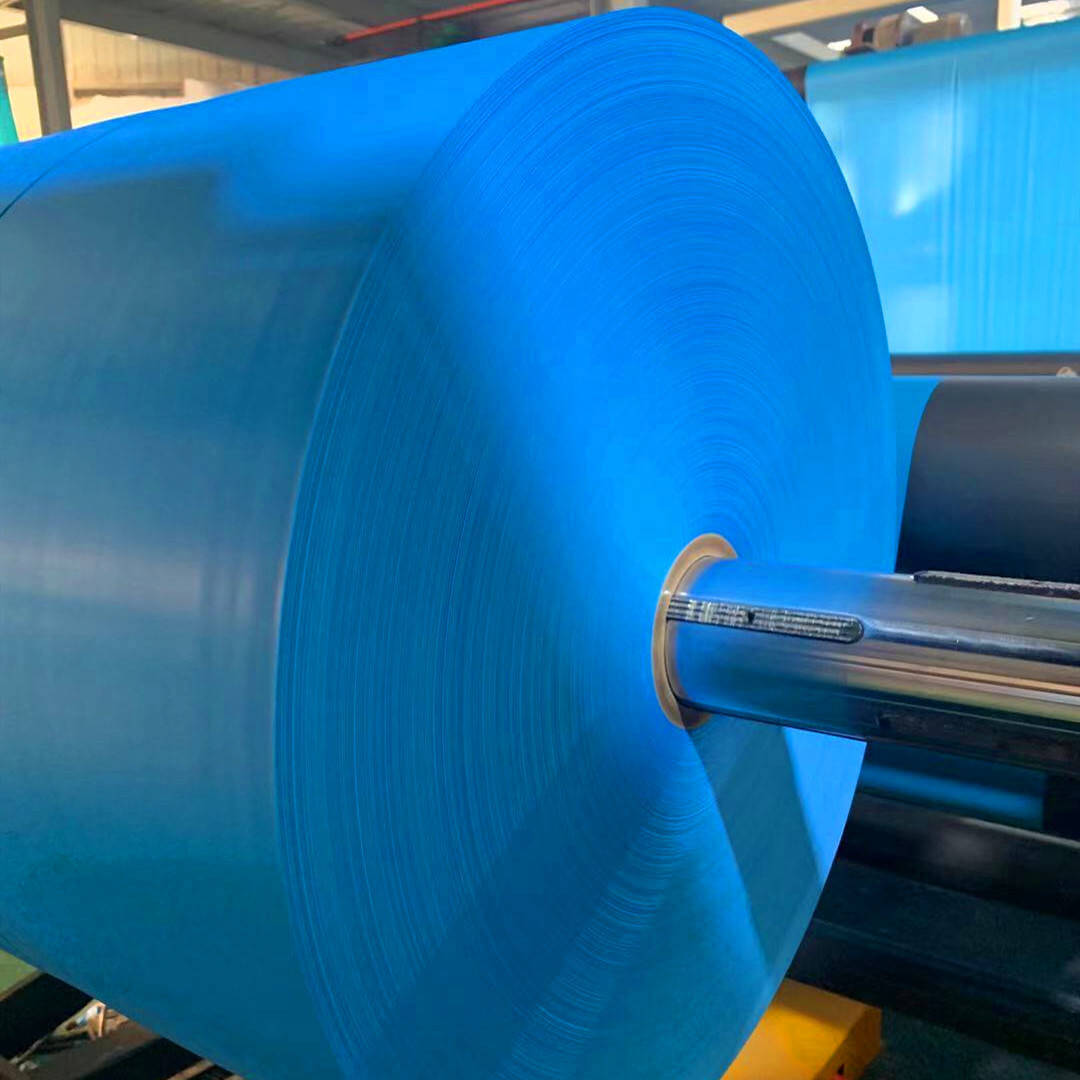

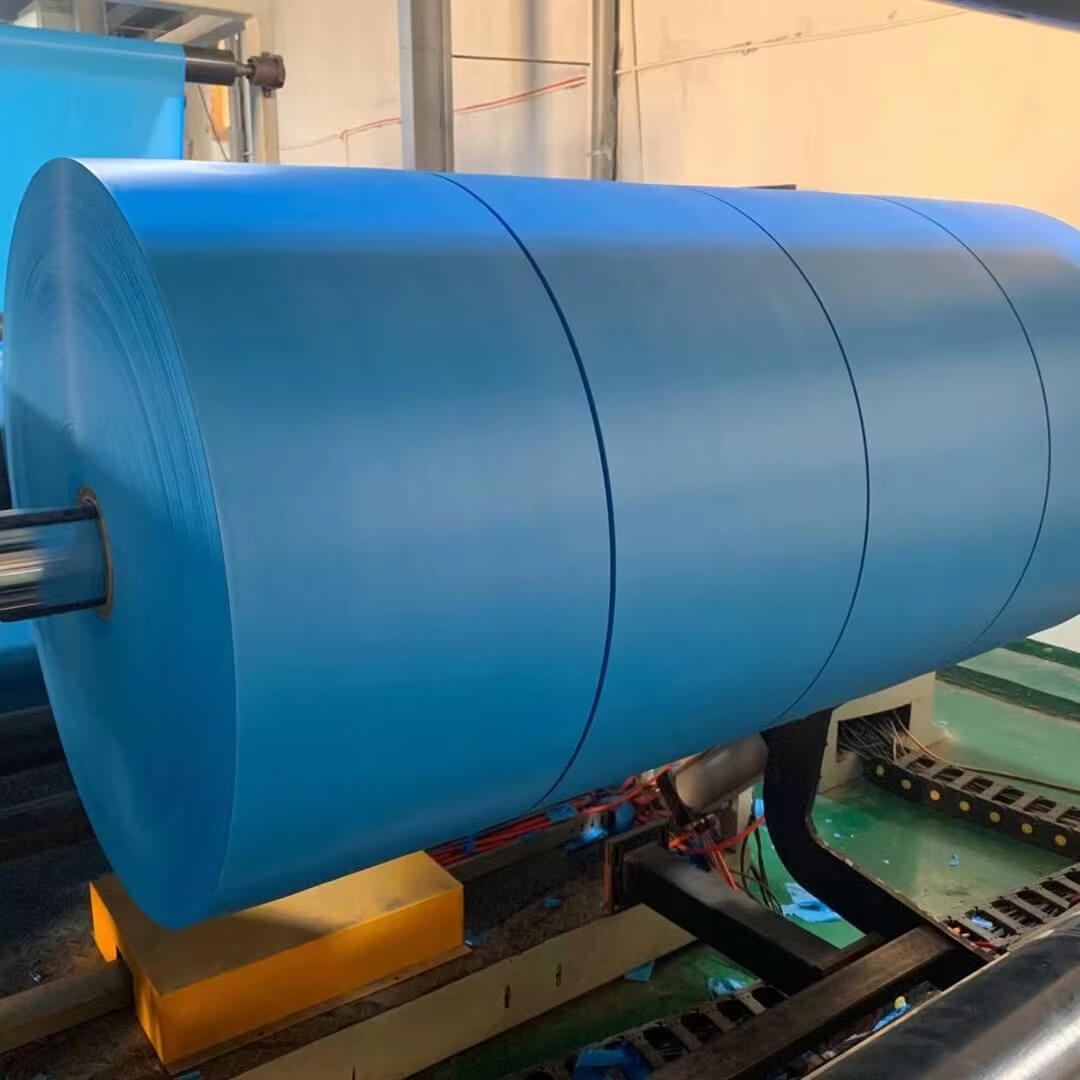

TPE (Thermoplastic Elastomer) is a flexible, rubber-like material that combines the properties of both plastic and rubber. TPE plastic films are widely used in various industries due to their excellent elasticity, durability, and ability to withstand environmental stress. Like PEVA, TPE is also eco-friendly and does not contain harmful chemicals like PVC, making it a safer alternative for many applications.

Advantages of TPE Films in Printed Fabric Applications:

- Design Flexibility: TPE films can be printed with various patterns, such as camouflage, cartoon characters, plant or animal designs. This makes them suitable for a wide range of outdoor, sporting, and fashion products. When printing complex patterns like camouflage, precise color matching is crucial. For example, the edges between deep green, green, and light green need to be carefully controlled to avoid overlap, ensuring a clean and accurate print.

- Camouflage Applications: In outdoor sports and survival gear, camouflage is a common requirement. TPE films can mimic natural surroundings effectively through precise color adjustment and pattern control, ensuring the materials blend into the environment. This is especially important for products like tents, backpacks, and clothing used in outdoor or military contexts.

- Durability and Weather Resistance: TPE has excellent durability, making it suitable for outdoor use. The material is resistant to extreme temperatures, UV radiation, and water, ensuring that it holds up well in tough outdoor conditions. This durability is crucial for outdoor gear like raincoats, tarps, and survival equipment that must withstand harsh environments.

- Color Accuracy and Fastness: When printing camouflage or other detailed designs, it’s essential that the colors remain vivid and resistant to fading. TPE films allow for high-quality color printing, and with proper pigment formulations, the color fastness can be maintained over time, ensuring that the products maintain their appearance even after prolonged exposure to the elements.

- Environmental Safety: TPE is a non-toxic material, making it a safer choice for both the environment and consumers. It’s often used as an alternative to PVC in products where human or environmental safety is a concern.

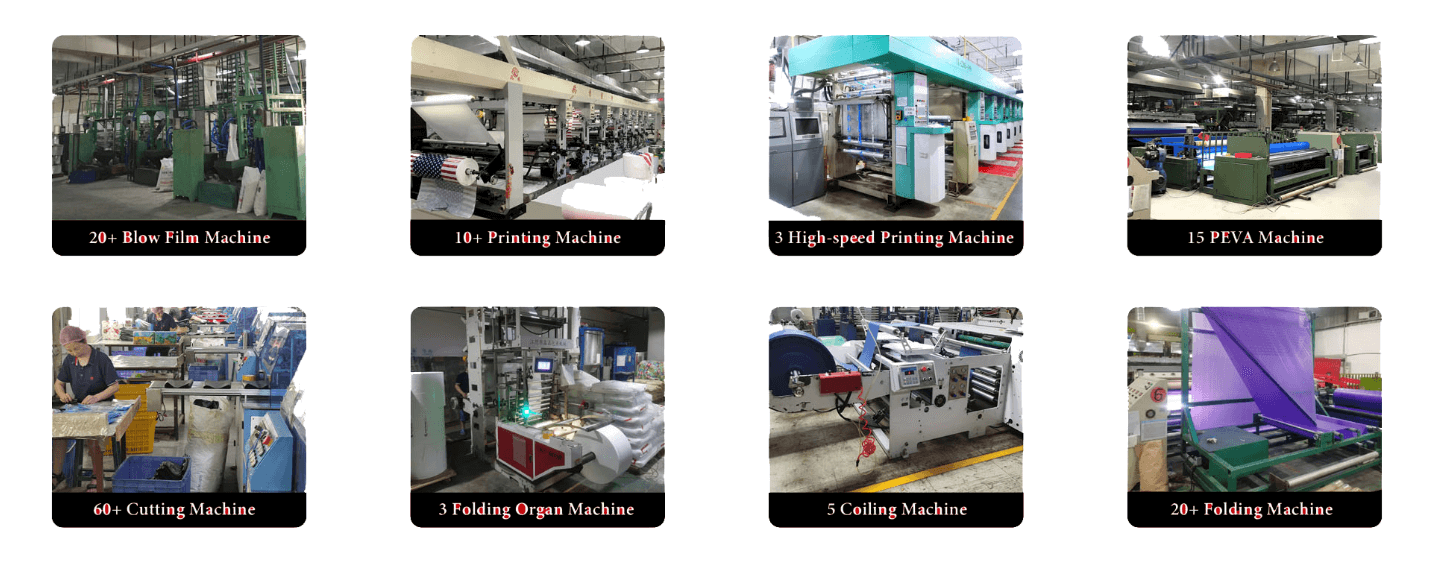

- Cost and Production Efficiency: TPE films are not only flexible in terms of design and application but also efficient to produce. The material can be processed in various ways, allowing manufacturers to produce high-quality, customized patterns at a reasonable cost.

In summary, TPE films offer the perfect balance of flexibility, durability, and environmental safety, making them ideal for outdoor products, especially where camouflage or other intricate designs are needed. The ability to precisely control color and pattern alignment ensures that the materials meet the demands of industries focused on outdoor survival, sports, and nature-based activities.