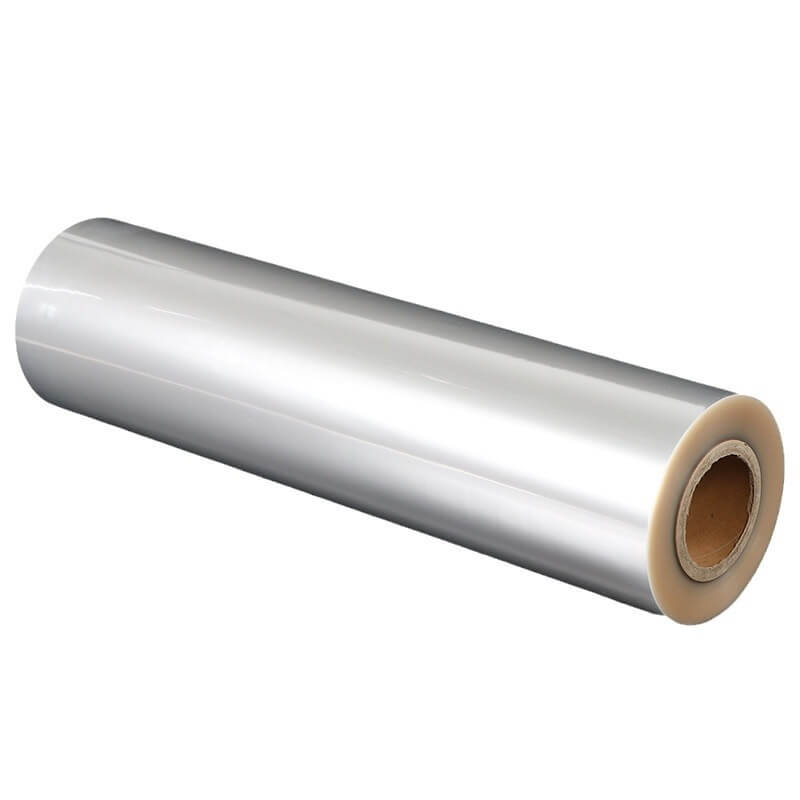

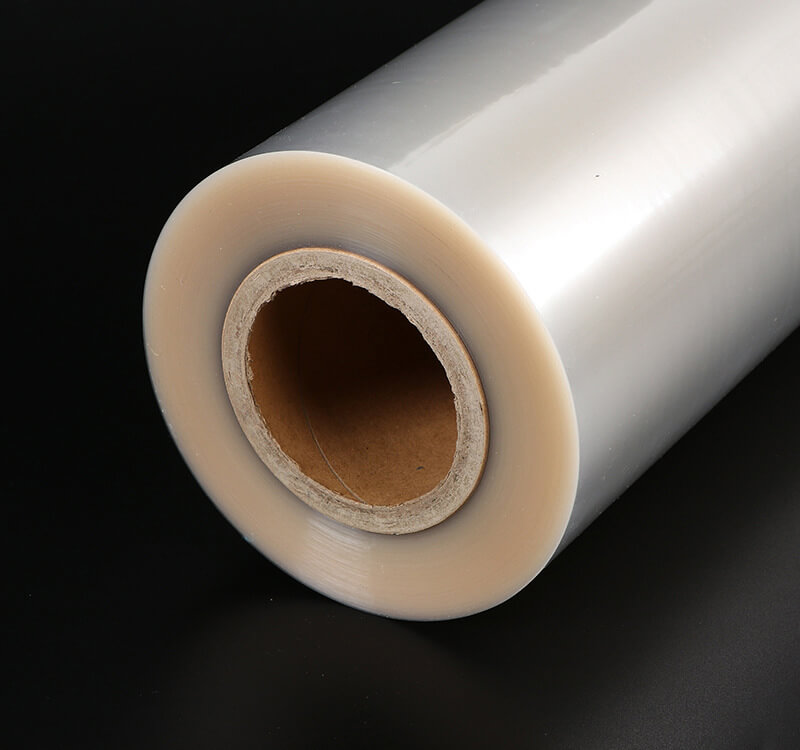

CPP Plastic Film (Cast Polypropylene Plastic Film) is a versatile material that is widely used in various industries due to its excellent properties such as high transparency, clarity, flexibility, and moisture resistance. CPP is produced through a casting process, where molten polypropylene is extruded onto a chilled roller, forming a thin and uniform film.

In the context of rainwear and protective gear applications, CPP film offers several advantages:

- Water Resistance: CPP film is naturally hydrophobic, meaning it provides a strong barrier against water. This makes it an ideal material for raincoats and other types of protective clothing designed to keep moisture out.

- Durability and Flexibility: The film is flexible and resistant to wear and tear, ensuring that raincoats made from CPP can withstand physical stress while allowing the wearer to move comfortably.

- Lightweight: CPP film is very lightweight, which is important for rainwear as it allows for easy portability and comfortable wear without feeling heavy or restrictive.

- Cost-effective: Given its relatively low production cost compared to some other materials, CPP is economically viable for producing disposable protective clothing, including rain ponchos or emergency rain gear.

- Transparency and Aesthetics: CPP films can be made transparent or semi-transparent, which is useful for raincoats that may require visibility or aesthetic appeal. It can also be dyed or printed with patterns, offering flexibility in design.

- Environmentally Friendly Variants: While standard CPP is not biodegradable, ongoing developments in eco-friendly versions of CPP aim to reduce the environmental impact, which is increasingly important in the production of disposable items like rainwear.

Overall, CPP plastic film provides an excellent solution for producing disposable and reusable raincoats, ponchos, and other protective clothing. Its combination of cost-efficiency, flexibility, and waterproof properties makes it an attractive choice in this market.